OEM & Consulting

OEM

RJL Systems has three decades of research, testing and engineering problem solving experience. We can put that expertise to work for you, helping your company design and manufacture advanced instrumentation and electronics for just about any industry. In the past, we have produced components for automotive, printing, machine-tool, transportation and medical device companies, including:

- An ultra high-speed ink-jet printing interface to secure coupons found in newspaper inserts

- A system to provide reliable absolute positioning using brushless resolvers. Used today to monitor each revolution of large stamping presses for the automotive industry.

- Products for small OEMs requiring extremely stable signal conditioning in hostile environments using constant currant low frequency carrier techniques

- Body composition analysis using a 50Khz carrier frequency — seen today in body composition scales found in many retail outlets

- A porous interface that prevents artificial nail extensions from lifting off the natural human nail

From concept to completion, from initial consulting to final assembly, RJL Systems will work with your company to design, create and manufacture the tools and components it needs.

OEM & Consulting

OEM Development

From Concept to Finished Product – RJL Systems…

RJL Systemshas developed basic concepts and ideas into new hardware and software products since 1979. RJL specializes in engineering and assembly electronic solutions for both large and small companies. Previous clients include machine-tool, printing, automotive, transportation, and medical appreciation purposes.

Where we have been – to name just a few. RJL has developed:

- an ultra high speed ink-jet printing interface for the George F. Valassis Company to secure coupons found in newspaper inserts. In addition, a porous air bearing was developed that greatly reduced paper ink smears when using high speed web presses. US patent 5,423,468.

- a system to provide reliable absolute positioning using brushless resolvers for the F. Joseph Lamb Company. US Patent 4,360,889 (11/23/82). This concept is used today to monitor each revolution of large stamping presses for the automotive industry.

- products for small OEMs that require extremely stable signal conditioning (LVDT’s, load cells and strain gauges) in hostile environments using constant current low frequency carrier techniques.

- the original concept of body composition analysis using a 50 Khz carrier frequency in the 1980’s and received FDA clearance in 1986. US device patent 6,631,292 (11/7/03). This concept is used today on popular body composition scales found in many retail stores.

- a porous nail interface that prevents artificial nail extensions from lifting off the natural human nail. US Patent 5,638,835 (6/17/97).

Where we are today

- We design and manufacture products using both through-hole and Surface Mount (SMT) components, using a variety of microcontrollers, to meet your cost and performance requirements.

- We can design and build advanced instrumentation and electronic solutions for any industry.

- From basic engineering, assembly and testing of SMT and through-hole circuit boards to complete turn-key instruments, systems, and software – we can do it all.

Please contact us and discuss your idea in confidence

Just a few examples

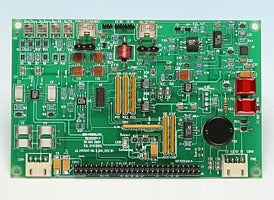

This processor module incorporates a high speed bipolar 16-bit ADC, an isolated power supply, isolated high-speed serial communication, and a high-contrast LCD display.

The processor board can easily be interfaced with a wide selection of analog sensory modules for a simple low cost embedded OEM system. Optional signal conditioning modules include LVDT’s, load cells, infrared sensors and safe biological interfaces. Power source options include a single 9 volt battery, three AA batteries or 12 volt mains.

This Bioelectrical Impedance Analysis (BIA) module measures resistance and reactance vectors at 50 KHz with 0.1 ohms of resolution. This BIA technology is the basis of all RJL Systems body composition products and is available to any OEM that wishes to incorporate it into present and future designs. In addition, the BIA module can be modified for improved sensitivity (0.01 ohms) without sacrificing signal to noise ratio. It is an ideal solution for measuring blood flow using pulse volume techniques, such as cardiac output and limb blood flow (series and parallel plethysmography).

RJL Systems builds reliable, battery powered, portable hand held instruments. The image to the left is a 3 AA to 5.0 VDC (0.5 amps) power supply that draws less than 20 micro-amps when off and has momentary On/Off control. Integrated low battery detection can shut down the device or deliver a signal to a MPU for further battery management. This advanced power supply uses 3 AA Alkaline or NiMh batteries and is only 2 x 2 inches in size.

Turning an instrument concept into a reliable finished product is RJL Systems’ specialty. The Quantum II Desktop BIA is one example of building an instrument on a highly modular platform to accommodate many different signal conditioning modules. The data acquisition and MPU modules can be customized to accommodate performance and cost requirements.